txhaj tshuaj molding kev pab cuam - Tuam Tshoj Hoobkas, lwm tus neeg, manufacturers

Nws tuaj yeem yog peb lub luag haujlwm los ua kom txaus siab rau koj qhov kev nyiam thiab ua tiav pab koj. Koj qhov kev txaus siab yog peb qhov khoom plig zoo tshaj plaws. Peb tau tos ntsoov rau kev mus rau kev sib koom ua ke rau kev txhaj tshuaj molding kev pabcuam,Txhaj Molding Tuag Tsim , Moulded Cheebtsam , Tsev Neeg Pwm Txhaj Moulding ,Gas Assist Moulding. Txais tos tuaj xyuas peb txhua lub sijhawm rau kev lag luam kev sib raug zoo tsim. Cov khoom yuav muab rau thoob plaws lub ntiaj teb no, xws li Europe, Amelikas, Australia, Chicago, Poland, Montreal, Canberra.Insisting ntawm lub siab zoo tiam kab tswj thiab cov neeg muas zaub kev pab, peb tam sim no tau tsim peb kev daws teeb meem los muab peb cov neeg yuav khoom siv. qhov pib nrog cov nyiaj tau txais thiab tsuas yog tom qab kev pabcuam kev ua haujlwm. Kev tswj hwm tus phooj ywg kev sib raug zoo nrog peb cov neeg yuav khoom, txawm li cas los xij, peb tab tom tsim kho peb cov kev daws teeb meem txhua lub sijhawm kom txaus siab rau cov kev xav tau tshiab thiab ua raws li kev tsim kho tshiab tshaj plaws ntawm kev lag luam hauv Malta. Peb tau npaj txhij los ntsib cov kev txhawj xeeb thiab ua rau kev txhim kho kom nkag siab txog txhua qhov muaj peev xwm ua lag luam thoob ntiaj teb.

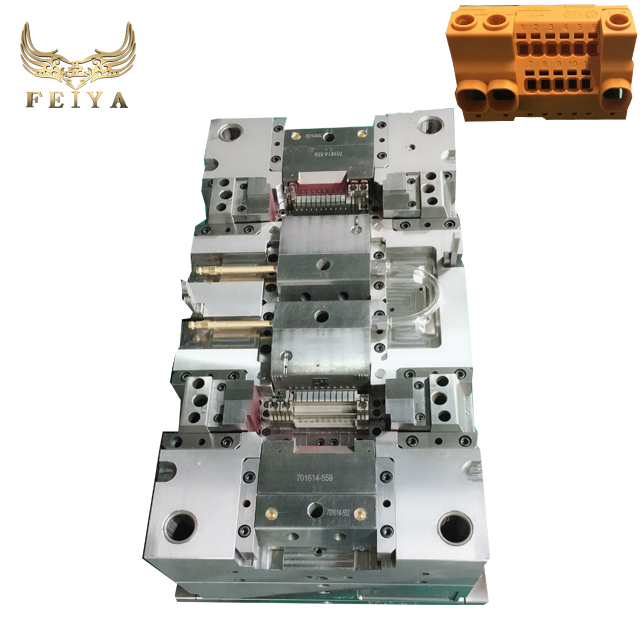

Yam khoom